- What Is the Role of Data Labeling in Machine Learning for Vehicle Defect Detection?

- Understanding Data Labeling in Machine Vision

- Role of Labeled Data in Vehicle Defect Detection

- Impact of Quality Data Labeling on Machine Learning Models

- Unique Macgence Benefits & Advantages in Vehicle Defect Data Labeling Services

- Conclusion:

Vehicle Defect Detection via Data Labeling in Machine Learning

The connection between machine learning and vehicle safety represents a technologically progressive juncture in the quickly changing digital ecosystem. The crucial duty of detecting vehicle defects, where accuracy and precision are crucial, is at the forefront of this convergence. Labeled data becomes essential to the effectiveness of defect detection systems as machine learning algorithms—especially those driven by deep learning—continue to influence vehicle safety in the future.

In this article, we explore the complex ecology of machine learning-based data labeling for automotive fault identification. We examine the critical part that data labeling performs in guaranteeing the safety and dependability of cars on the road, from comprehending the basic significance of labeled data to disentangling the complexity of fault variety. By closely examining the challenges, strategies, and outcomes of data labeling, we illuminate the path toward enhanced defect detection systems and universally safer roadways.

What Is the Role of Data Labeling in Machine Learning for Vehicle Defect Detection?

A crucial component of automobile safety, vehicle flaw identification, is depending more and more on machine learning. But here’s the big issue: for these algorithms to work well, enormous volumes of precisely labeled data are needed. Machine learning algorithms may find it difficult to correctly discover flaws without sufficient data labeling, which might pose a safety issue.

The intricacy of car flaws makes this problem worse. These can vary in severity, from little paint blemishes to serious structural damage, and each calls for a unique set of labeling guidelines. Machine Learning models may misclassify problems as a result of inconsistent or erroneous data labeling, which can exacerbate the issue and perhaps result in expensive misdiagnoses.

To assure the consistency and correctness of the data supplied into these models, consider data labeling in machine learning. If every kind of problem is properly labeled, machine learning algorithms will be able to identify and classify automotive defects more accurately. This improves overall vehicle safety and reliability and increases the accuracy of problem identification.

Understanding Data Labeling in Machine Vision

1. Deep Learning’s Critical Role: Deep learning plays a vital role in machine vision. Particularly in applications where defect detection is required, such as automobile safety.

2. Dependency on High-Quality Labeled Data: Access to a substantial amount of precisely labeled data is a prerequisite for machine vision algorithms to function well. Inaccurate defect identification by algorithms might result from imprecise labeling, hence elevating safety hazards.

3. Difficulties Associated with Defect Diversity: Defects in vehicles can range considerably, from little problems like paint chips to significant structural damage. The data labeling procedure is made more difficult by the need for distinct labeling criteria for each type of fault.

4. Effects of Inaccurate or Inconsistent Data Labeling: Machine vision algorithms may misread flaws as a result of inaccurate or inconsistent data labeling. This misunderstanding may result in false positives, which are expensive and jeopardize the dependability of systems for detecting defects.

5. Significance of Accurate Labeling Techniques: Employing exacting labeling techniques guarantees the precision and coherence of the information supplied to machine learning models. Algorithms need this level of precision in data handling in order to identify and classify different types of car problems.

6. Impact on Safety and Reliability: Appropriate data labeling raises the accuracy of fault detection. Which boosts vehicle safety and overall dependability.

These points summarize the fundamentals of data labeling in machine vision. Emphasizing in particular how crucial it is to improve the efficiency and dependability of fault detection systems in the car sector.

Role of Labeled Data in Vehicle Defect Detection

1. Enhanced Algorithm Effectiveness: Precisely annotated data improves the efficiency of complex algorithms by allowing them to accurately detect flaws, thereby lowering safety hazards.

2. Misinterpretation Risk: Machine learning models may perceive errors wrongly as a consequence of inconsistent or inaccurate labeling, leading to costly false positives.

3. Mitigation of Safety Threats: Properly labeled data enables machine learning models, which assist in reducing safety threats by efficiently identifying defects and keeping risky autos off the road.

4. False Positive Prevention: Accurate labeling reduces false positives, which decreases the cost of unnecessary repairs and boosts the efficiency of defect detection systems.

These concepts emphasize the significance of labeled data in enabling machine learning algorithms. To detect and classify automobile defects, hence improving vehicle safety and dependability.

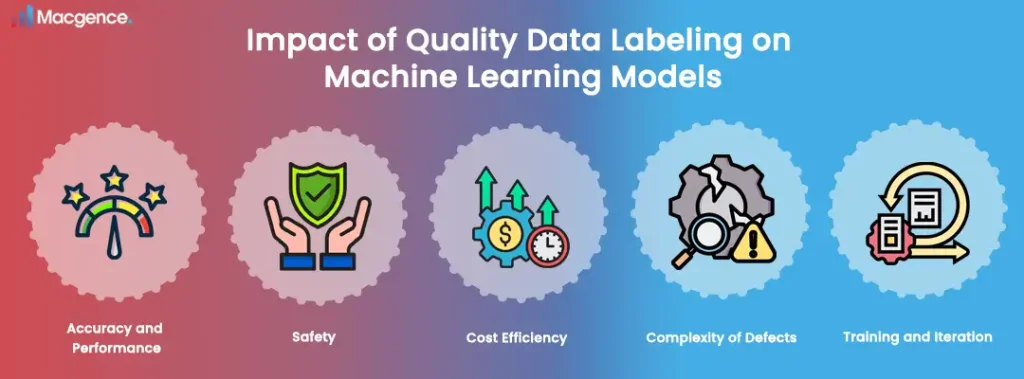

Impact of Quality Data Labeling on Machine Learning Models

Machine vision requires the use of deep learning, particularly in the area of automobile safety. Nevertheless, a substantial amount of precisely labeled data must be available for these complex algorithms to function well. Any shortfall in diligent data labeling can impede Machine Learning models from accurately pinpointing defects, thereby escalating safety hazards. Complications arise due to the diverse nature of vehicle defects, spanning from trivial paint imperfections to severe structural impairments. Each category demands unique labeling parameters. Erratic or erroneous data labeling can mislead Machine Learning models into misinterpreting defects. Amplifying the issue and potentially triggering costly false positives.

Unique Macgence Benefits & Advantages in Vehicle Defect Data Labeling Services

Vehicle defects pose a significant problem for Machine Learning applications, often leading to inaccurate predictions and flawed decision-making. This issue is further aggravated by the complexity of data labeling, a critical step in Machine Learning. Fortunately, a solution exists in the form of Macgence data collection and annotation services. With their advanced technology and AI-driven tools, they simplify the task of handling AI training data. Providing localized and globalized insights from data in any language and context. Their services are trusted by global giants and have been instrumental in supporting and scaling AI initiatives worldwide.

Conclusion:

The relationship between fault detection and data labeling is a keystone of technical advancement in the field of vehicle safety. Machine learning algorithms can reliably and safely discover and categorize vehicle faults through careful labeling, improving road safety. It is impossible to overestimate the importance of precise data annotation as we traverse the complexity of automotive faults. In the future, a dedication to superior data labeling techniques will propel the development of fault detection systems, guaranteeing safer roadways for all. We can create a future where every vehicle serves as a symbol of dependability and safety. In addition to being a means of mobility by embracing innovation and teamwork.

FAQs

Ans: – Ensuring machine learning algorithms can accurately identify and categorize car faults through accurate data labeling contributes to increased road safety.

Ans: – Vehicle flaws can range greatly, from little paint blemishes to significant structural damage, and each one needs unique labeling guidelines. Which can make the process of data labeling more difficult.

Ans: – Inaccurate or inconsistent labeling may compromise the reliability of defect detection systems. Causing expensive false positives and misunderstandings of faults.

You Might Like

October 11, 2025

Why Your AI Can’t Understand Humans: The Multimodal Conversations Datasets Gap

Your conversational AI is failing, and you probably don’t know why. It responds to words perfectly. The grammar checks out. The speed is impressive. But somehow, it keeps missing what users actually mean. The frustrated customers. The sarcastic feedback. The urgent requests are buried in casual language. Here’s what’s really happening: your AI is reading […]

October 10, 2025

Why Your Self-Driving Car Needs Perfect Vision: The LiDAR Annotation Story

Imagine you’re driving down a busy street. Your eyes are constantly scanning – pedestrians crossing, cars merging, cyclists weaving through traffic. Now imagine teaching a machine to do the same thing, except it doesn’t have eyes. It has lasers. And those lasers need to understand what they’re “seeing.” We’ve seen many product launches that aim […]

October 9, 2025

What is Synthetic Datasets? Is it real data or fake?

Picture this: You’re building the next breakthrough AI product. Your models need millions of data points to learn. But there’s a problem. You can’t access enough real-world data due to various factors, such as compliance issues, security factors, and specific needs. Privacy regulations block you. Collection costs are sky-high. And even when you get data, […]